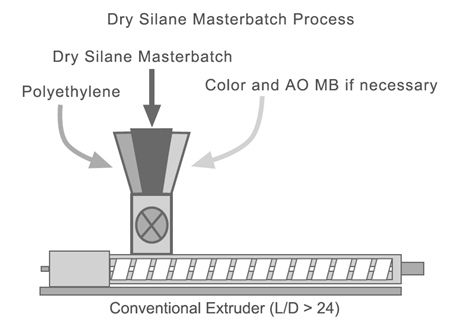

Dry silane is a modified one-step technology for crosslinking polyethylene; it utilizes the porous PE carrier to absorb the vinyl silane cocktail to get the dry, pellet form vinyl silane crosslinking agent masterbatch. One major concern of the conventional one-step liquid process is the necessity of having 1) a precise injection system for the liquid silane blend. and 2) a long extruder (L/D = 30). This equipment is expensive and has high cost of maintenance. Furthermore, the handling of liquid silane mixtures needs care to assure safety.

Dry silane technology was developed to allow the use of conventional extrusion equipment with a solid silane masterbatch. The heart of this technology is the use of porous polymers as carriers for the silane blends. Producers of wire and cable, pipes, film, sheet and injection-molded parts can thus blend dry silane masterbatch with polyolefin pellets. Dry silane masterbatch must be metered through a suitable gravimetric feeding system in order to ensure an accurate dosing of the silane masterbatch. Ideally the feeder should be equipped with separate feeding sections for color masterbatch and base resin. The blend can then be extruded with a conventional extruder, molded or formed, and allowed to moisture-cure.

Benefits to the user of dry silane masterbatch are:

Existed extruder (L/D =24) can be used,

Masterbatch allows use of local base resins,

Easy to use,

Faster start-up (shorter down-time),

More consistent dispersion,

Flexible, easily tailored for end application,

Larger diameter XLPE extrusions are feasible,

Lower silane consumption can be achieved,

Elimination of screw-slip (no liquid in barrel),

Less scrap.

Dry silane is a modified one-step PEX-b processing to produce XLPE cable and PEX-b pipe, pellet form dry silane masterbatch can ensure the accurate dosing of the silane crosslinking agent and simplified the equipment requirements of the traditional Monosil one-step processing.

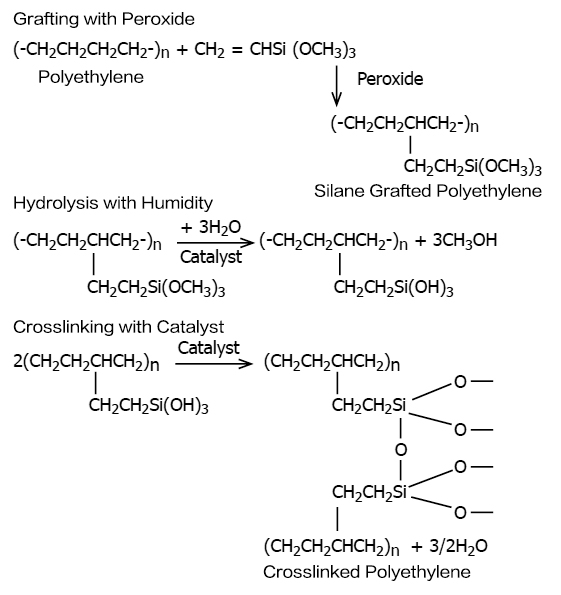

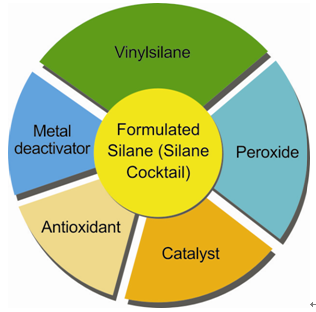

During the extrusion phase the liquid silane cocktail which contains vinyl silane, peroxide, tin catalyst, antioxidant and metal deactivator will be squeezed out and released; their basic chemical mechanism is same to the regular PEX-b processing:

At first Grafting stage, vinylalkoxysilane is grafted via its vinyl groups on polyethylene through a peroxide initiated free radical reaction. After the grafting, polyethylene can still be processed as a thermoplastic resin like regular PE resin as it has not cross-linked. Only this grafted polyethylene treated with moisture like hot water bath (65~100℃), steam bath or even at ambient the grafted vinylalkoxysilane will hydrolyze and condensed, thus the polyethylene will final be cross-linked.

Polyethylene is a volume leader in the global plastic industry with numerous applications. However, its low upper service temperature makes ordinary polyethylene unsuitable for the applications requiring continuously continuous use under stresses at temperatures up to 100℃ (for example in hot water pipes) or occasional increases in temperature above a certain limit during temporary electrical overloads on cables. By cross-linking of polyethylene some important properties would be drastically improved (Table 1). Some applications include heat shrinkable products (in cable installation), heat-resistant foodstuff packaging (up to 200℃), foams for thermal insulation, and chemical-resistant seals. Moreover, cross-linked polyethylene is more resistant to water treeing and tracking which are undesirable in cable insulation & jacketing industry. Besides the capability of cross-linked polyethylene in withstanding higher electric loading, its ability to tolerate thermal shocks, and the small thickness required for insulation, makes it a suitable candidate for cable insulation & jacketing industry. Polyethylene has the melting point of 100~130℃, however, after cross-linking no flow would be noticed even at 150℃ where elastic behavior prevails.

Property of PE resin

Property change of PE resin after crosslinking

Melt Index

Decrease

Density

No changes/ slightly decrease

Molecular Weight

Significantly increased

Tensile Strength

No changes/slightly increase

Elongation-at-break

Decrease

Impact resistance

Significantly improved

Abrasion resistance

Greatly improved

Stress-crack resistance

Greatly improved

Elastic properties

Greatly improved

Environmental stress crack resistance

Increase

Resistance to slow crack growth

Increase

Temperature resistance

Greatly improved

Chemical resistance

Significantly increased

Main applications of silane crosslinking polyolefin are as below:

1. Wire and Cables (insulation & jacketing layer for LV and MV)

2. Pipes (hot water, underfloor, gas, chemicals, sewage)

3. Heat Shrinkable products (tubes, sleeves)

4. Films (creep resistance and shrinkable applications)

5. Foams (heat insulation)

6. ……

Compared to other PEX-b processing our dry silane has the following advantages:

1. Standard & existing extruders can be used to produce XLPE (i.e. existing PVC extruders might be sufficient and 24 L/D extruders are enough)

2. Easier startup and Flexibility of use (no liquid, better handling & safety)

3. Can run cross-linked and thermoplastic materials on same line.

4. Larger diameter XLPE extrusions are feasible. (through more consistent dispersion),

5. Dry Silane masterbatch allows use of local base resins (i.e. producer can choose resins from his preferred or current suppliers).

6. Dry Silane masterbatch can be tailored for end application (i.e. varying cure speed)

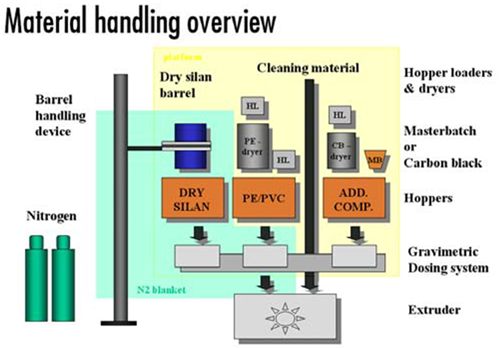

A typical Dry-Silane processing unit for the low voltage power cable production consists of the following units:

Raw materials

Base polymer:

The Dry-Silane technology can be used for a wide range of LDPE and LLDPE grades ensuring optimized cost effectiveness.

Dry-silane masterbatch:

Dry-silane masterbatches are delivered in the form of solid free flowing pellets. The dry-silane masterbatches are available with different silane loadings (concentrations). Depending on the different carrier resins and formula, the silane loading can be in the range of 40% up to 70%.

Antioxidant masterbatch:

In case unstabilized base materials are used an antioxidant masterbatch must be used.

Color masterbatch:

It is used for color identification purposes. Usually color masterbatches are fed manually to the dosing system.

UV - stabilizator:

Aerial cables require the application of a UV stabilizator which is handled similar as a color masterbatch.

Raw material preparation

Dry-silane masterbatches are sensitive towards humidity; dry components have to be used.

Predrying of the base polymer to water contents below 300 ppm is required. The polymer transport from the dryer to the dosing station has to be carried out utilizing desiccant air coming from the drying system.

Never dry the dry-silane masterbatch!

In extrusion lines special care is taken that dry-silane masterbatches are in contact with silane resistant materials only.

Handling the dry-silane masterbatch

The shelf life time of the dry-silane masterbatch is apx.6 month. Once when the original packing is opened the dry silane masterbatch should be used up immediately.

Storing of the dry silane has to take place in cool and dry conditions.

Transport respectively storage temperatures above 55°C have to be avoided.

Dosing system

A gravimetric dosing system is absolutely necessary for dry-silane masterbatches with a high silane loading.

For masterbatches with a low silane loading, a volumetric system could be used, but we strongly recommend also for these masterbatches a gravimetric system.

Extruder

For applications, in which Dry-Silane as well as PVC compounds have to be processed, electrically heated/air cooled 24 D extruders are recommended.

Typical output figures of a 120 mm 24D machine are 270 kg/h XLPE, respectively 800 kg/h PVC (with individual screws)

For applications, in which Dry-Silane only has to be processed, 30 D machines are a good choice. The XLPE output of a 120 mm 30 D extruder is apx. 300 kg/h.

In general we use for Dry-Silane applications shallow grooved feeding zones in combinations with barrier type screws.

Separate screws for PVC and dry-silane are provided. For PVC, standard nitrited screws are used; dry-silane XLPE requires screws with a special surface treatment.

Screw heating/cooling

A high performance screw cooling system is essential. Typically cooling capacities of apx. 50 kW is used for a 120 mm main extruder.

We use water based units because of the higher operational dynamic compared to oil based units.

Crosshead

For insulation applications on smaller cross sections usually fixed centered crossheads are used. Compression tooling is used for round conductors.

It is important that the parallel zone on the extrusion tools is kept short.

Best results have been achieved with max. 4mm parallel length.

Manually centered crossheads are commonly used for insulation applications on larger cross sections.

Sector shaped conductors are processed by means of tubing tools.

Die heating system

For improving the surface quality and to reduce the die drewal effect, a powerful die heating system is provided.

The die heating temperature has to be in the range of 300 ~ 320°C, therefore commonly burners (open flames) are used for this application.

Cooling trough

The use of a hot water section after the crosshead is essential. The cooling water temperature in this section is in the range of 60~80°C.

Crosslinking

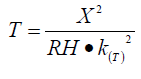

For an estimation of the crosslinking time the following formula can be used:

T=Crosslinking time in hours

X=Insulation wall thickness in

mm

RH=Relative air humidity in %

K(T)=temperature factor

K(95°C)=1,2.10-4 K(90°C)=1,0.10-4

K(75°C)=0,8. 10-4 K(20°C)=0,1.10-4

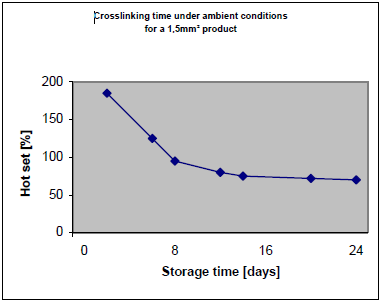

Hot set test

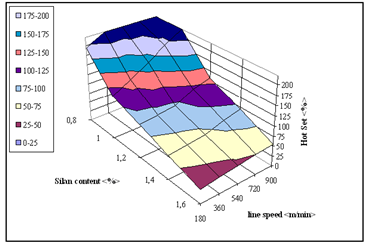

The achievable hot set values depend on the absolute silane dosing rate.

The following chart shows the relation between hot set values, absolute silane concentration and line speed.

The data shown have been collected on the basis of a 1,5mm² insulated conductor.

Summary

The Dry-Silane process offers significant advantages compared to the other crosslinking methods for low voltage cables.

The Dry-Silane Technology can be considered as state of the art for this specific cable types in the meantime.

Cable manufacturers can utilize their well-established Monosil or even normal Sioplas extruder to use dry silane.

For any additional information please do not hesitate to contact Capatue.

Notice: Some data above quotes from the document of Rosendahl Nextrom GmbH.

Our dry silane products are mainly used for XLPE wire & cable and PEX-b pipe, those masterbatches contains up to 5 different ingredients:

Ingredient

Function

Vinyl Silane

Crosslinking agent; always it is a basic ingredient of the dry silane.

Peroxide

Initiator; always it is a basic ingredient of the dry silane.

Catalyst

Accelerate the reaction speed of hydrolysis and crosslinking rate; always it is a basic ingredient of the dry silane.

Antioxidant

Stabilize PE resin during extruding and long turn working, should be used in unstabilized PE resins.

Metal Deactivator

Inhibit the catalytic effects of metal ions especially copper, should be used cooper cables.

Surely other ingredients like UV inhibitor could be added according to the customer’s request.

According to different application, different resins & conductors type we develop several different dry silane formula to meet the market demands. They contain different ingredients and have their own features.

Grade

Components contained

Functional

Application

VS

PO

CA

AO

MD

XLM30

Y

Y

Y

N

N

Crosslinking

Cable

XLM31

Y

Y

Y

N

N

Crosslinking

Cable

XLM40

Y

Y

Y

Y

N

Crosslinking

Cable

XLM50

Y

Y

Y

Y

Y

实亿国际Crosslinking

Cable

XLM51

Y

Y

Y

Y

Y

Crosslinking

Cable

XLM52

Y

Y

Y

Y

Y

实亿国际Crosslinking

Cable

XLM53

Y

Y

Y

Y

Y

Crosslinking

Cable

XLM60

Y

Y

Y

N

N

实亿国际Crosslinking

Cable

XLM70M

Y

Y

Y

Y

Y

实亿国际Crosslinking/Coupling

Cable

XLM71

Y

Y

Y

N

Y

Crosslinking/Coupling

Cable

XLM73

Y

Y

Y

N

Y

Crosslinking/Coupling

Cable

MB-A10E

Amino silane

N

N

N

N

Crosslinking

Cable

VS: Vinyl silane, PO: Peroxide Initiator, CA: Catalyst, AO: Antioxidant, MD: Metal Deactivator.

Grade

Features

XLM30

It is a cross-linking system developed for use in moisture cross-linking of low and medium voltage cables. It does not contain any metal deactivator or antioxidant; therefore it must be used with stabilized base resins or with suitable masterbatches.

XLM31

It is a 1 step cross-linking agent specially developed for the manufacture of cross-linked LLDPE low- and medium voltage cables. When using with unstabilized base resins, an antioxidant masterbatch must be used.

XLM40

It is a 1 step cross-linking agent and fully stabilized designed for the manufacture of cross-linked PE LV & MV cables with aluminum conductors.

XLM50

It is a 1 step cross-linking agent for unstabilized LDPE and LLDPE resins. Designed for LV & MV power cables with copper conductors and jacketing. It is already equipped with A/O and MD.

XLM51

1 step cross-linking agent for unstabilized LDPE and LLDPE, designed for copper/aluminum conductor LV & MV power cables. It is equipped with A/O and MD to pass the ageing test 10 days @ 135°C on copper wire.

XLM52

It is a multi-component cross-linking system, including thermal stabilizer and copper inhibitor to pass heat ageing test 10 days @ 135°C on copper wire. The masterbatch is developed for use in moisture cross-linking of low- and medium-voltage power cables based on non-stabilized resins.

XLM53

It is a multi-component cross-linking system, including extra thermal stabilizer and extra copper inhibitor to pass 7 days at 150°C aging test on copper wire. It is developed for use in moisture cross-linking of low -voltage power cables based on non-stabilized resins and all types of jacketing.

XLM60

It is a 1 step cross-linking agent for HDPE pressure pipes. If using the masterbatch with an unstabilized carrier, the use of a separate masterbatch containing antioxidant and metals deactivator is recommended.

XLM70M

It is a multi-component cross-linking system which includes a thermal stabilizer and a copper inhibitor, developed for use in moisture cross-linking of halogen free flame retardant compounds and semi-conductive compounds for MV cables.

XLM71

It is a cross-linking system to be used with stabilized, developed for use in moisture cross-linking of halogen free flame retardant compounds and semi-conductive compounds for MV cables.

XLM73

It is a cross-linking system to be used with either stabilized halogen free flame retardant compounds developed for use in moisture cross-linking or with unstabilized HFFR compounds but a stabilized carrier of the dry silane (e.g. DSHF).

MB-A10E

It is a 40% masterbatch of amino silane 3-aminopropyltriethoxysilane in a porous carrier.

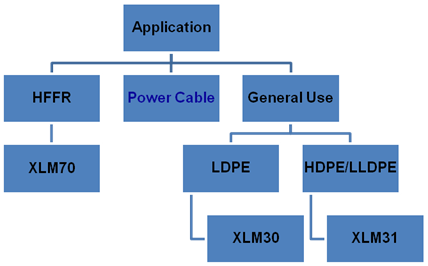

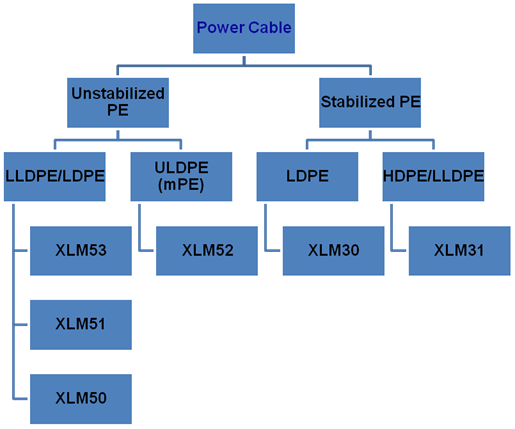

Briefly we could use the following decision tree to choose the suitable grade for your applications: